As common as they are, electromagnetic devices are not as widely understood. An electromagnet uses an electrical current to generate a magnetic field. The strength of that field is directly proportional to the level of current supplied to the magnet, and the field’s polarity can be flipped by changing the direction of the electrical current. Electromagnets serve a variety of purposes in many day-to-day technologies, particularly in electromechanical and electronic devices.

We’ll cover some of the most common uses of electromagnets in the world today, both in consumer products and for industrial applications, making many modern technologies possible.

Real World Electromagnet Applications in Electronics

Most people don’t directly see electromagnets in their daily life, but they are no less often used. Electromagnets are found in countless consumer and commercial products, including:

- TVs

- Audio Equipment

- Computers

- Cars

- Elevators

- Copy Machines

- MRI/CT Scan Machines

Real World Electromagnet Applications in Power Generation

Generating power involves converting sources of primary energy into electric power. An electric generator stores mechanical energy in the form of electrical energy by using a wire coil in a magnetic field. This is done by rotating the coil, which induces a current, and industrial-scaled applications accomplish this with a large, rapidly spinning turbine to produce massive amounts of electrical current.

This electrical energy can be stored and converted back into mechanical energy for a variety of purposes – such as running a motor. To do so, an electromagnet is supplied with a reverse current, creating a magnetic field that causes the magnet’s coil to spin, along with anything connected to it.

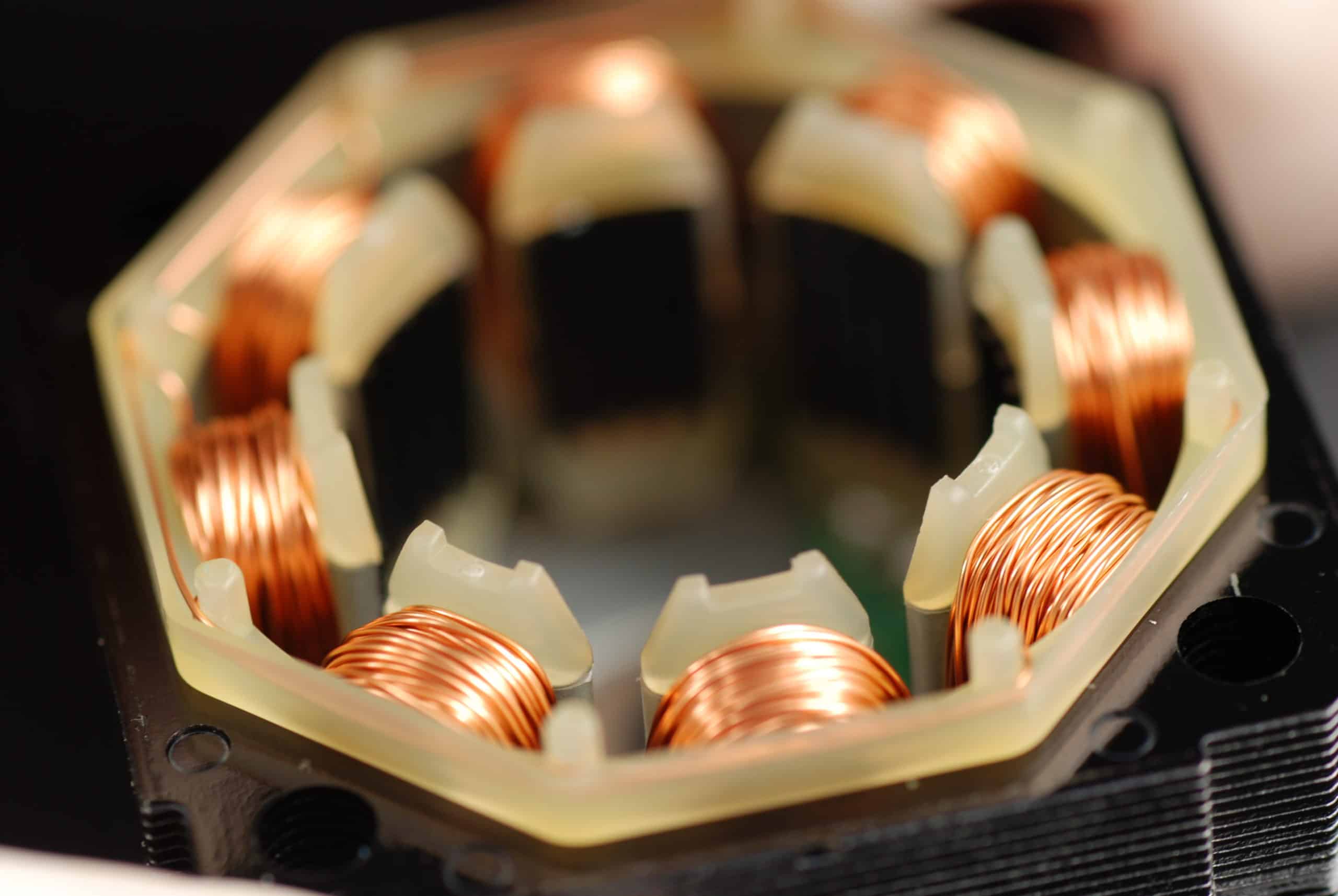

Electromagnets make it possible to convert mechanical energy into electricity, and then back into mechanical energy. The electromagnetic device that converts these energies is called an actuator, which consists of a stationary and a moving component (such as a rotor), where the magnetic fields produce torque and force that can be harnessed. This same principle makes it possible to use an electromagnet’s induction coil to measure the magnetic field itself, making electromagnets capable of functioning as sensors.

To summarize, electromagnets are used in four different ways in the power generation process:

- Generators

- Motors

- Actuators

- Sensors

Real World Electromagnet Applications in Medicine

Medical devices such as Magnetic Resonance Imaging machines (MRIs), use magnets thousands of times more powerful than your average kitchen magnet to generate signals in the radio-frequency range, which the device then measures and translates into images. This results in highly detailed pictures of bones, organs, and various tissues.

Magnets are also applied in some cancer treatments, where a doctor injects magnetically sensitive fluid into the area around the tumor and uses a powerful magnet to generate heat in the body. The goal is to kill the cancer cells without harming the healthy tissues.

These are just two common medical uses of magnets – others include:

- Scanners

- X-ray equipment

- Dialysis machines

- Disinfectant dispensers

- Electromagnetic therapies

Real World Electromagnet Applications in Aerospace

Aerospace engineers have developed an almost entirely separate field of magnetics. Specialized uses involve sending finely controlled current and voltage to receiving systems to maintain altitude and other flight dynamics. In reverse, this also enables them to track the location and flight path of various aircraft and devices.

Much of aerospace engineering would not be possible without electromagnetic technology. Electromagnets power many standard and specialized aerospace devices, such as:

- Flight control covers for both commercial and combat aircraft

- Missile programs

- Aircraft loudspeakers

- Traveling-wave tube (TWT) radar

- Permanent Magnet (PM) generator rotor assemblies

- Fuel pumps

- Flow regulators

- Cryogenic magnets suited for space environments

- Magnetic holders for aircraft seats

- Position-calibration and speed sensors

- Air-compressor components

- Motorized generators

- Tachometer generators

Electromagnets from Custom Coils

Not many technologies are as ubiquitous to modern life while remaining largely hidden from direct experience as electromagnets. Just as electromagnetic devices have driven much of modern technology forward without being often credited as such, Custom Coils, Inc. has been quietly and dutifully driving the electromagnetic industry forward since 1978.

With a highly customer-centric business model, our expert engineers work closely with every client to design and manufacture precision-engineered electromagnets for a wide variety of end uses. For any questions or to let us know about your electromagnetic needs, don’t hesitate to request a quote or contact us.