Modern Imaging and scanning technologies require electromagnets and other electrical assemblies with very specific design criterion. Typical design challenges include working with very tight space limitations and the sourcing of materials, capable of operating under extreme thermal environments. These high power applications are inherently risky. As such, design and manufacturing considerations require careful thought and planning.

Coil, Electromagnet, & Inductor Uses in the Imaging & Scanning Industry

Electromagnetic imaging and scanning systems utilize many design specific electrical and mechanical components that influence system functionality and imaging quality. Among the most important components are electromagnets, which consist of cylindrical, current-carrying coils wrapped around a magnetic core.

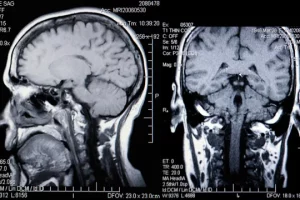

In MRI machines, electromagnets for imaging and scanning are responsible for generating a powerful magnetic field that facilitates a uniform alignment and stimulation of protons in the human body. The electromagnetic coils, also known as inductors, serve as an antenna that receives radiofrequency (RF) signals from a sample or area of interest and transmits that information to a computer. This information can then produce detailed images of bones, organs, or soft tissue that allow doctors to evaluate and monitor diseases and other conditions.

Applications

Coils, inductors, and electromagnets are essential components in several industries for things like electric motors, actuators, transformers, and magnetic devices for recording and storing data. Regarding imaging and scanning magnets, these components are typically custom-engineered based on various system parameters and space or resistance requirements. Common applications include:

- MRI machines. In MRI machines, electromagnets generate the required magnetic field strength to stimulate protons while occupying minimal space within the machinery, helping medical professionals look for health concerns like tumors.

- Magnetic resonance (MR) spectroscopy. MR spectroscopy equipment assesses biochemistry in the brain to pinpoint any changes that could be attributable to tumors, strokes, or epileptic seizures. The machine achieves this using electromagnetic radiation from custom electromagnets.

- Magnetic particle imaging. Magnetic particle imaging is an emerging tomographic imaging technique that uses multiple large electromagnets to detect iron-oxide nanoparticle tracers throughout the body at a cellular level.

- Imaging mass spectrometry (IMS). Custom-designed electromagnets generate an electromagnetic field that allows for molecular imaging that determines the ratio of ions’ mass as compared to their charge, plotting a medical sample’s isotopic print.

Custom Coils Capabilities

Custom Coils creates customized electromagnetic assemblies, coils, and other components for imaging and scanning equipment in quantities varying from one-off parts to large-volume production runs. We manufacture electromagnetic coils from various core materials and wire gauges in different coil lengths and diameters. Our team offers in-house, comprehensive services with an emphasis on optimizing product design for performance, manufacturability, and affordability. Depending on the needs of your project, we can assist you with:

- Material selection

- Development and rapid prototyping

- Design and engineering

- Establishing critical coil design parameters

- Project management or consulting

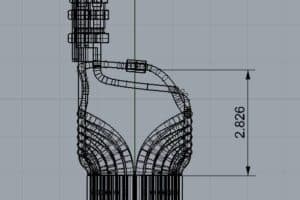

- CAD modeling

- Tooling development

- Cost optimization

- Testing and quality inspection

As an ISO 9001:2015- and 13485:2016-certified company, we are committed to quality and innovative efficiency. Custom Coils can help clients navigate the challenges associated with finding the right electromagnetic components for an application, particularly when there are thermal management requirements or other exacting specifications.

We recently partnered with a company to create an electromagnet for a medical imaging system using hyperpolarized Xenon gas to measure pulmonary function. Given the specialized nature of the equipment, the electromagnet required a unique design to meet the necessary field specifications and electrical parameters while adhering to tight space constraints. We achieved design optimization by providing material recommendations to maximize performance and longevity, incorporating application-specific mechanical features based on the equipment’s functional requirements, ensuring that the design could tolerate the unusual operating conditions, and directly attaching a mechanical bracket to secure mounting for a high-performance end product.

Electromagnetic Solutions at Custom Coils

Coils and electromagnetic assemblies are critical to the efficiency and dependability of advanced imaging and scanning technologies. At Custom Coils, we work with companies in the demanding medical and research areas of this sector to create high-quality, industry-compliant coils, inductors, and electromagnets. Our team understands that, particularly in critical industries, there is no one-size-fits-all solution, and so we draw on decades of experience to collaborate with you and find the material and design that will ensure accuracy and longevity in your product.

To learn more about our specific capabilities and the industries we serve, please contact us today or request a quote if you are ready to begin your project.