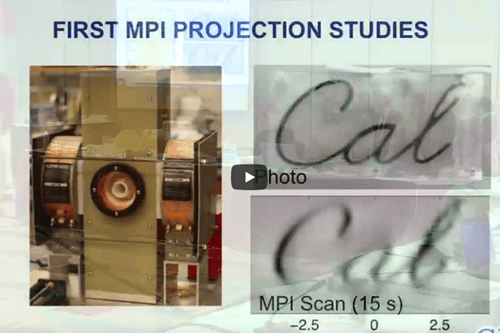

Custom Coils was approached by a research organization from University of California, Berkeley, working on a project to design a scanner, which uses magnetic particle imaging for stem cell therapy. The purpose of this project was to compare magnetic particle imaging, for tracking stem cells in vivo, to current methods like MRI, CT, or XRAY.

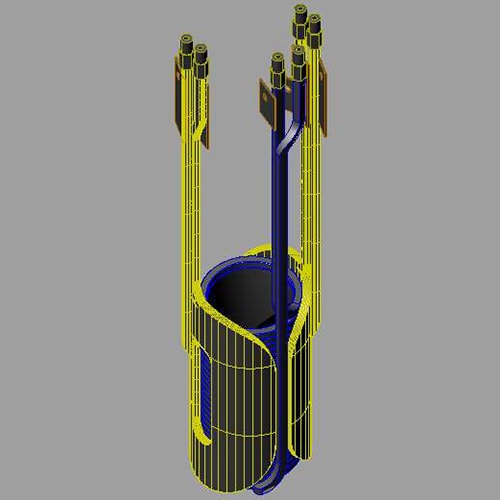

High power input and a limited physical footprint required a magnet design which could manage the thermal impact of extreme power, and very tight mechanical tolerances. A heavy shaped DDG insulated hollow core magnet wire was identified as the conductor source of choice. Thermal modeling data determined that greater flow rate, through multiple water lines, ensured that maximum operating temperature stayed below their threshold. Thermal limits were defined, in part, by maximum temperature ranges of the conductor, insulation, epoxy, solder, and tapes, which were researched and provided by Custom Coils. The water lines were welded in series. Custom Coils engineers designed all process tooling, necessary to ensure optimal layer to layer compaction for maximum dielectric integrity, throughout the winding and heat curing process. Custom Coils designed a test protocol to meet desired electrical and mechanical specifications.

Our close collaboration with the design team enabled the creation of a complex electromagnet assembly which became a critical component to validating a new technology approach, driving the advancements of this revolutionary concept to significantly improving image resolution.

To learn more about this advanced coil project, see the table below or contact us directly.