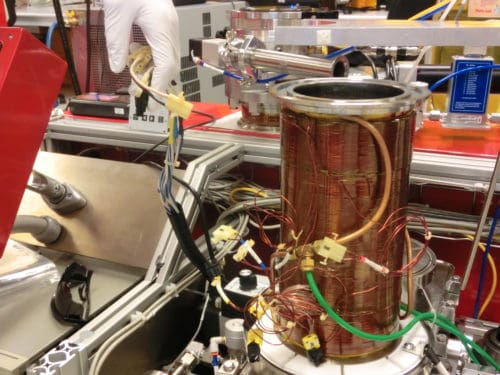

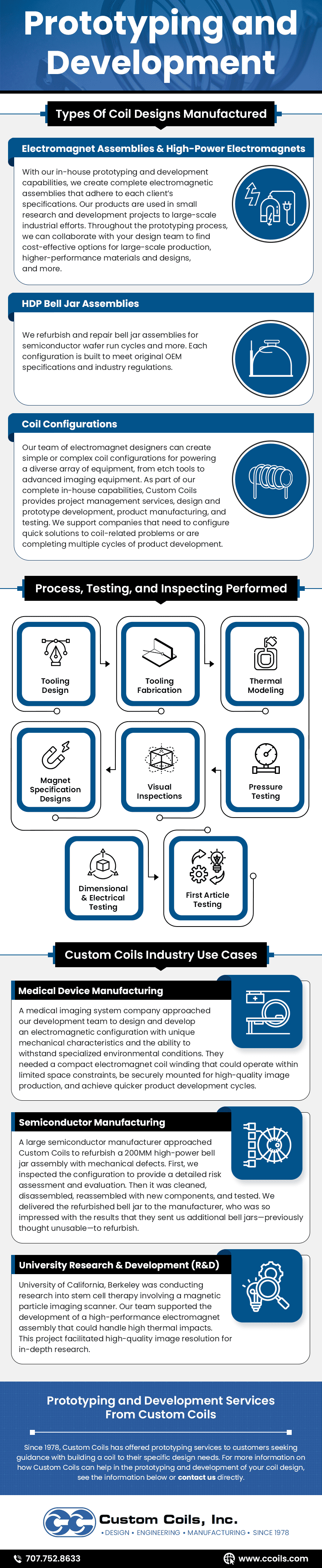

Custom Coils is more than just a coil manufacturer. We understand the complexities involved in electromagnetic coil design and are here to partner with and fully support our customers with initial design, product development, prototype, testing, and full production release.

A critical step in the product life cycle is the prototyping, development, and testing phase to ensure the design meets our customer’s objectives and is optimized for production manufacturability, quality, and cost. Custom Coils will provide support for prototype manufacturing, from single coil winding to larger batches, or variations of windings with similar design parameters. We support our customers’ test requirements to validate their designs and suggest design improvements to improve quality and cost.