Semiconductor processing and test equipment rely on high-quality, precision components, which are utilized at several levels, in the fabrication of semiconductors. At Custom Coils, Inc., we design and manufacture high-quality and precision custom coils for semiconductor processing and testing applications. Learn how this industry’s equipment utilizes coils for the varying production stages, and how Custom Coils can assist you in fabricating specialty coils for your organization.

How the Semiconductor Processing & Test Equipment Industry Uses Coils

To develop a semiconductor, the process begins with a silicon wafer substrate as the semiconductor base. The wafer goes through multiple processing stages, such as cleaning, deposition, coating, UV light exposure, etching, ion implantation, and more. Magnetic coils generate electromagnetic fields in specific processes, in which the wafer is exposed, on the way to becoming a semiconductor die. Variations in mechanical and magnetic coil specifications generate electromagnetic fields with different properties, including field strength, size, or consistency.

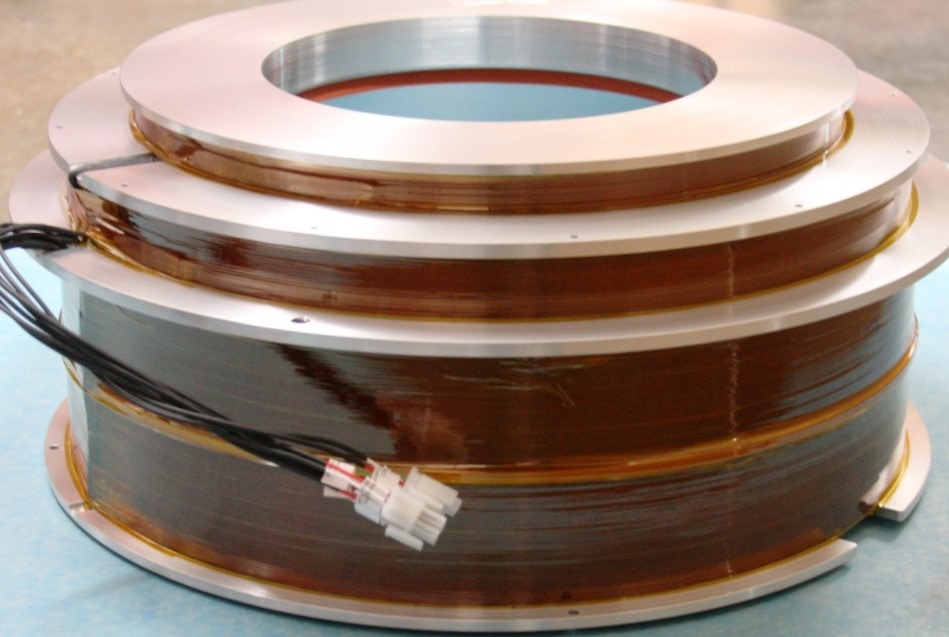

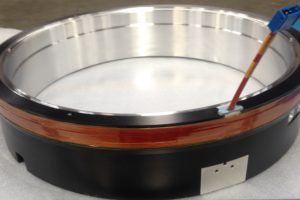

At Custom Coils, we specialize in the design and production of electromagnets that work in dielectric and polysilicon etch applications. For example, we collaborated with a large manufacturer, which was looking for an electromagnetic design solution to mount four coils on the sides of a chamber. The precise specification of the magnet was critical to reducing the “fringe effects” on the wafer during the release of plasma. Since the introduction of the original 200 mm application, Custom Coils has delivered over 10,000 units, which are operating in tools all over the world. Custom Coils also provides refurbishing services for many electromagnet and RF source components which are being utilized in systems across the globe. In an HDP dome assembly, used in a chemical vapor deposition tool, our team was able to restore the original ceramic dome to its current specification and reassemble it with new components. Our customer was able to successfully run this tool and process several thousand wafers, with the refurbished dome assembly, for several years.

Applications for Coils in Semiconductor Processing & Test Equipment

Electromagnets and coil assemblies are designed in a multitude of tools that are part of the critical process of semiconductor production. The design criterion and material selection considerations are critical pieces of the puzzle required to achieve state-of-the-art process outcomes. Examples of specific semiconductor processes of which Custom Coils is currently supplying electromagnetic components include:

Dielectric Etch Process

Coils generate electromagnetic fields that ionize plasma during the electric etching process on semiconductor wafers. Dielectric etching selectively removes insulative and conductive layers from deposition stages. Custom Coils has over 40 years of experience designing coils for this application, and hundreds of active designs in tools located all over the world.

Ion Implant Process

During this process, dopants (charge carriers) are implanted on a silicon substrate’s solid surface to improve the wafers’ conductive properties. Radiofrequency (RF)-source assemblies assist the doping of silicon-integrated circuitry components. Our team specializes in designing RF-source solutions, partnering with design engineers worldwide.

Metal Deposition Process

Just as coils can etch into semiconductor wafers, coil-achieved electrical current can also assist in the metal deposition in wafer creation. Precisely generated electromagnetic fields allow manufacturers to deposit thin, finely controlled layers of metal on the semiconductors to increase material thickness for better protection against corrosion. In some cases, operators may need to apply an inductor directly to a machinery adapter to provide exact evenness in the magnetic field and the resulting deposition.

HDP-CVD and PECVD Processes

High-density plasma chemical vapor deposition (HDP-CVD) and plasma-enhanced chemical vapor deposition (PECVD) processes require their own unique coil configurations and designs. RF coils are frequently designed and utilized in this tool application.

Materials

The materials we use to create precision coils for a myriad of semiconductor production applications include:

- Acrylic tube

- Phenolic tube

- Copper magnet wire

- Dacron Mylar Dacron (DMD) insulation

- Double day glass (DDG) insulation

- Mylar insulation

- Nomex® insulation

- Epoxy

- Glass cloth tape

- Hollow core conductor

- Radiation-resistant resins

- Silicone elastomer

- Ultra-temp material

Process of Fabrication of Semiconductors

Semiconductor production, from start to finish. involves multiple stages and process steps. At Custom Coils, we specialize in providing design and manufacturing services of electromagnetic components for many of the stages in this long line of process steps. We collaborate with our customers to identify the optimal design considerations, establish a prototype plan that meets specific design criteria, then design a manufacturing process of record, to ensure the highest quality and repeatability. Our manufacturing processes include CNC machining, automated and hand-wound coil winding and bending, welding and soldering, heat curing, and vacuum impregnation.

RF Coils

Coils (inductors) are utilized in RF match assemblies, used across several process applications.

Custom Coils Capabilities

For an experienced partner who understands the critical components within the semiconductor manufacturing industry, choose Custom Coils. We know that there are no one-size-fits-all solutions for electromagnetic coils. Our team can support your process with comprehensive services from material consultations, design analysis, and prototype manufacturing through production, assembly, and product testing. We can also analyze existing parts to problem-solve, repair, and refurbish related components.

Whatever the project, we at Custom Coils will collaborate with you to find the right coil type, material, and finish to enhance your system’s performance and meet your exacting specifications. Contact us today to discuss your next project or request a quote for pricing details.

Ready To Start Your Project?

The industry leader in custom design for magnetic coil applications for over 45 years.