At Custom Coils, our expertise in coil design and manufacturing, allows us to offer collaborative design solutions which utilize high tech processes, with cutting edge technology. The project highlighted here was developed for a manufacturer of semiconductor processing equipment, who needed an electromagnet for the ionization of plasma on a tool used in the dielectric etching process.

Our support of this client included a co-engineered design effort, and the successful delivery of fully tested prototype units. Collaboration began at the project’s inception, and included the creation of solid models, a complex set of drawings and BOMS, and comprehensive test specification.

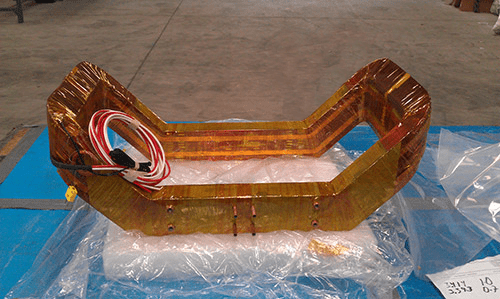

The electromagnet featured a rectangular shape with bent ends which provides greater field uniformity. It also included the addition of cooling plate assemblies with water channels which were embedded in the center of the magnet. This feature allowed for a constant operating temperature below design threshold. The prototype was manufactured using a number of processes including CNC machining, our coil winding system, a coil bending operation, welding/soldering system, and heat curing using an industrial oven. It also utilized materials such as film insulated magnet wire, high temperature epoxy, various insulating materials, copper plate/copper tube, PTFE coated lead wires, and was finished with Kapton tape.

To ensure the precision and integrity of the prototype units, we employed various quality measures such as custom fabricated test fixtures, and gauges, as well as functionality testing. This high powered electromagnet, was engineered, manufactured, and delivered inside of the 8 week turnover that the customer required.

To learn more about this project, or the processes used to manufacture it, see the table below or contact us directly.