Solenoids: Working Principle,

Types & Applications

Comments Off on Solenoids: Working Principle,Types & Applications

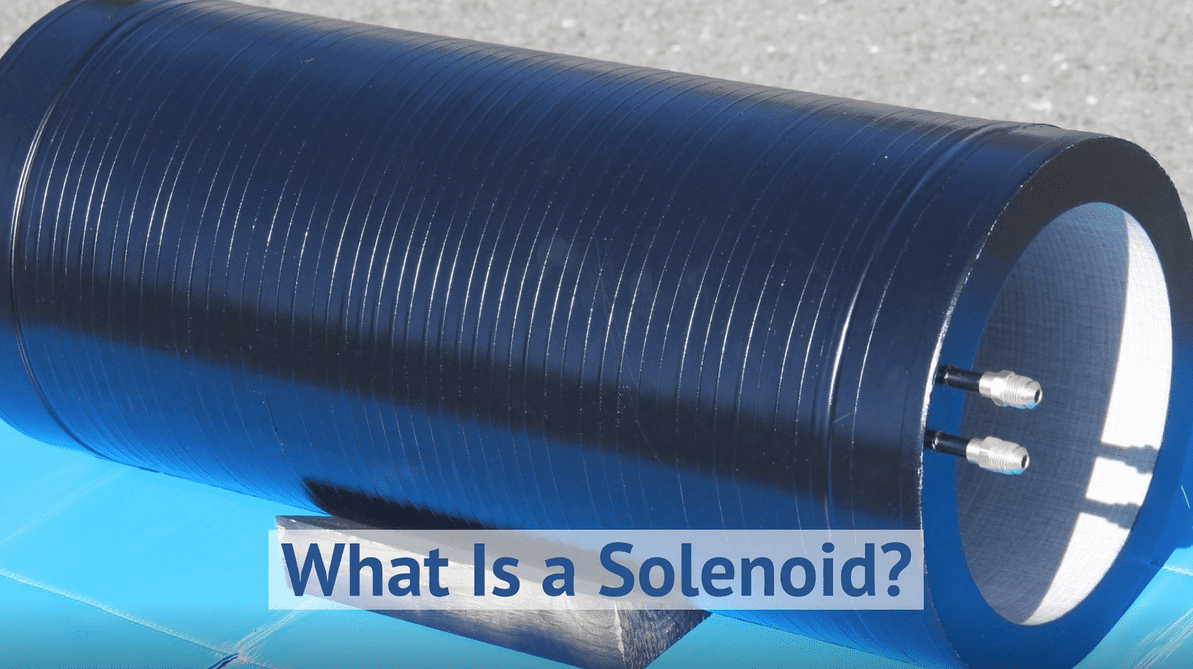

A solenoid is a variety of electromagnet consisting of a copper wire coil wound tightly into a helix, an iron or steel housing, and a mobile plunger made of magnetic material. When an electric current passes through the coil, the solenoid produces a magnetic field and converts that magnetic energy into mechanical motion. Essentially, a solenoid converts electrical energy into mechanical work through electromagnetic forces. For example, solenoids are often used as a valve to actuate a push or pull force on a magnetic component in a device. Solenoids can also act as a switch in electromechanical devices. These electromagnetic devices are used in hundreds of everyday applications from doorbells to car ignition systems.

Custom Coils designs and develops quality solenoids to meet the needs of your application. We work efficiently and expertly to create specialty coils for our valued customers.

How Does a Solenoid Work?

When an electric current is applied to a solenoid, it creates a powerful magnetic field that attracts or repels a magnetic material, ie magnetic plunger, to move inside of its housing. As the plunger moves back and forth, it creates the mechanical motion that powers the intended component.

Solenoid magnets have an advantage over conventional permanent magnets because their magnetism can be switched on or off as needed by removing or applying the electrical current. You can adjust the strength of the magnetic pull by increasing or decreasing the electrical current. Additionally, the direction of motion can be reversed based on the direction of current flow through the solenoid.

There are two basic types of solenoids: valve and electric. In valve solenoids, a constant electric current is applied to the solenoid. Once activated, the piston or plunger retracts to open the valve that would otherwise block the flow of material. Once the electromagnetic field is broken, the solenoid is deactivated and the valve will close.

Electric solenoids are used to close circuits to allow engines to run. When the solenoid receives the electric current it pulls nearby metal components in place to create a closed circuit. Constant electric current is required to keep the circuit closed and the engine running.

Types of Solenoids

- AC-Laminated Solenoid: These solenoids comprise a wire coil and a metal core made with laminated metal, which helps reduce stray currents and optimizes the solenoid’s performance. AC-laminated solenoids have an inrush current, which delivers a greater amount of force in the initial stroke. This also means they can deliver more strokes than DC-laminated solenoids. Common applications of AC-laminated solenoids include locks, medical devices, industrial equipment, vehicles, and other equipment that need immediate operation.

- DC C-Frame Solenoid: Some applications may also use a DC C-frame solenoid, which features a C-shaped frame that wraps around the wire coil. This solenoid uses a stroke operation with more control, making it suitable for many everyday applications, like circuit breakers, camera shutters, scanners, coin counters, and gaming machines. Though it utilizes DC configuration, DC C-frame solenoids are compatible with AC power equipment.

- DC D-Frame Solenoid: Like C-frame solenoids, DC D-frame solenoids operate with more controlled strokes and are compatible with AC power applications. The main difference is that the D-shaped frame is made with two joined pieces that shield the coil. ATM machines, gaming machines, and gas- and blood-analyzing equipment often use these solenoids.

- Linear Solenoid: This is one of the most widely recognized solenoids. Linear solenoids feature a coil-wrapped metal core, delivering pushing or pulling force to operate a piece of equipment. This operation makes it popular for use in many starting devices, such as vehicle ignition systems. Linear solenoids are also ideal for use in electric locks to enable the door to withstand significant forces when locked.

- Rotary Solenoid: If an application needs a simple automatic control process, it may use a rotary solenoid, which has the same essential components as other solenoids but with a unique mode of operation. Rotary solenoids function using a metal core situated on a grooved disc. The grooves are sized according to the slots on the solenoid’s body, and ball bearings allow for improved ease of motion. When it’s powered on, the core withdraws into the solenoid’s body and the disc core rotates. When it’s powered off, a spring pushes the disc core back to its starting position. Because they are more robust than other types of solenoids, rotary solenoids are often used in industrial applications like automated shutters and lasers.

Applications for Solenoids

Without realizing it, you use solenoids every day. Solenoids vary in size and power, making them suitable for countless applications. Powerful solenoids consist of many coils, create strong magnetic fields, and can be used to power large machinery. A smaller, less powerful solenoid can be used for smaller functions like ringing a doorbell. Some of the more common applications for solenoids include:

- Mechanical or fluid control valves

- Starting a car

- Ringing a doorbell

- Door locking mechanisms

- Nail guns

- Air conditioning controls inside vehicles

- Powering signal systems in the railroad industry

While these simple but effective devices are used to actuate many common devices, they have become highly utilized in nontraditional physical motion applications, such Ion Beam Accelerator systems.

There are innumerable applications for solenoids, as any device that requires force to create mechanical movement can benefit from their functionality.

Custom Coils is Your Expert on Solenoid Design and Manufacturing

Solenoids are important devices in much of the technology we use daily. These devices are effective, versatile, and easy to implement in your systems. From conception to production, the experts at Custom Coils will partner with you to determine your specific needs and customize the right solenoid device for your application. Contact us to learn more about our services or request a quote today.