A Guide to Magnetic Particle Imaging (MPI)

Comments Off on A Guide to Magnetic Particle Imaging (MPI)

Medical professionals rely on access to high-quality preclinical imaging tools to monitor healthy and diseased tissue, make diagnoses, and develop treatment plans. Three tomographic preclinical imaging options have been available over the last few decades: positron-emission tomography (PET), computed tomography (CT), and magnetic resonance imaging (MRI).

Each has its own drawbacks, from using ionizing radiation to achieve images or lacking the capability for real-time 3D volume imaging. However, magnetic particle imaging (MPI), a new, cutting-edge preclinical imaging technology, promises to provide superior insight into our biology and diseases’ effects on it down to the molecular level.

What Is Magnetic Particle Imaging (MPI)?

MPI creates three-dimensional, finely detailed images of organs, tissues, cells, and molecular-level specimens. It utilizes specialized imaging hardware coupled with tracers of specific metal particles called super-paramagnetic iron oxides (SPIOs). Once a medical professional has introduced the tracers into the patient’s targeted systems, the patient moves to the MPI scanner’s imaging region, where they’re exposed to a magnetic field. The SPIOs interact with the equipment’s field gradient, creating detailed particle images of the examined tissue, system, or region with optimal resolution and contrast.

The Problems MPI Solves

MPI systems address two critical issues that other modern-day scanning options struggle with:

- Profusion imaging. Medical professionals run billions of dollars worth of profusion scans each year to track the flow of blood through tissue or an organ like the heart or brain. However, the images often lack the detail or resolution that would allow for early medical detection and intervention.

- Radiation and contrast agents. Scanning technology often requires the use of radioactive tracing elements and contrast agents. Patients cannot regularly be exposed to these volatile substances, so medical professionals can only take a limited number of scans, further exacerbating the risk of missed disease indicators.

Alternatively, MPI can pick up on small abnormalities, so it assists with diagnosing diseases sooner because of the superior sensitivity of the technology. Medical professionals won’t need a high volume of SPIO tracers to produce an image, and SPIOs are also safer for patients.

How MPI Works

Rather than detecting tissue itself, MPI works by tracking the movement of SPIO particles in specific tissues, organs, or areas of the body. Medical professionals can even target the application of tracers to focus on a single factor, like CAR T-cells.

These systems have two permanent, sizable MPI magnets directed at each other, generating a strong magnetic field. However, in the middle of the MPI magnetic field, there is a field-free, or fueled-free, region (FFR) that generates little magnetic force in a known location. This field-free region will interact with any SPIO nanoparticles with which it crosses paths, making these particles flip, which the MPI receiver coil then interprets as a signal.

The MPI moves the magnetic field very quickly over the patient in the equipment’s imaging region, causing all of the SPIO particles to flip. These signals, as the technology understands them, pinpoint a specific location and MPI translates them into a quantitative, finely detailed 3D image through tracer distribution.

How MPI Differs From Other Imaging Techniques

MPI operates very differently from other imaging methods, providing a higher degree of image quality. Though they have different magnet architectures, MPI is often compared to MRI, which uses magnets to identify resonance from the H nucleus and other nuclear spins. MRI technology has common applications in anatomical imaging but doesn’t provide the same fine-tuned imaging on a small scale that MPI can.

Rather than picking up on nuclear signals, MPI detects nanoparticles’ magnetization, allowing for a much greater degree of sensitivity and better success in cellular imaging tasks. Compared to PET imaging and MRIs, MPI is also a faster imaging option.

Applications of MPI

With various uses in the medical sector, key MPI applications include:

- Early cancer, cerebrovascular, and cardiovascular disease detection. With sub-micromolar sensitivity, MPI doesn’t have to use radiation but can still achieve reliable screening results for earlier, better illness detection.

- Perfusion imaging of the heart. Similarly, its sensitivity allows healthcare professionals to receive enhanced heart images for better evaluation.

- Monitoring treatment progress. Given its spatial and temporal resolution capabilities with a zero background signal for endogenous tissue, use of long circulation half-life particulate, and speedy access, MPI is adept at monitoring ongoing treatments.

Benefits of MPI

MPI is particularly advantageous because of its superior sensitivity, speed, and safety compared to other imaging options. It doesn’t rely on radiation like PET or x-rays like CT, so it makes more frequent screenings possible. Also, the system is easy to operate, even without dedicated personnel, so medical researchers can gather data on their own.

Most importantly, MPI produces industry-best, high-resolution images that can dramatically improve early detection, diagnosis, and treatment development. It has the potential to one day scale from preclinical to clinical applications as an alternative to radiation-using PET and SPECT scans.

Custom Coils Provides Magnetic Coils for the Medical Industry

Coils and electromagnetic assemblies are critical to the efficiency and dependability of advanced imaging and scanning technologies. Our expert team works with companies in the demanding medical and research areas of this sector to create high-quality, industry-compliant coils, inductors, and electromagnets. We understand that, particularly in critical industries, there is no one-size-fits-all solution, and so we draw on decades of experience to collaborate with you and find the material and design that will ensure accuracy and longevity in your product. Contact us to learn more about our capabilities for your components’ full development cycle, or request a quote today for pricing details.

Electromagnets in the Aerospace Industry: Thrusters

Comments Off on Electromagnets in the Aerospace Industry: Thrusters

Electromagnetic propulsion (EMP) requires two primary components: an electromagnet to generate the magnetic field and a propulsion component. EMP uses a current from the magnetic field to accelerate the object. Through Lorenz Force, the electrified conductor encounters a force in a perpendicular direction to the magnetic field and the current. If a liquid or gas is used for propulsion instead of a conductor, this force is called Magneto Hydro Dynamic drive.

The concept of electric propulsion is gaining popularity in the aerospace industry for use as a spacecraft thruster. For decades, the aerospace industry has led research into electric propulsion, focusing on electric propulsion diagnostics. The aerospace industry has long applied advanced diagnostics to thruster characterization, and now it is using various plasma probes to analyze the electric potential, density, and electron temperature of plasma. Aerospace researchers were the first to characterize electric propulsion thrusters using various diagnostic tools, including electromagnetic radiation measurement.

How Electromagnetic Propulsion Will Work

While space travel has thus far been limited to chemically-propelled rocket engines, in the early 21st century, antimatter, nuclear fusion, and light propulsion techniques are becoming promising means for space travel. New spacecraft without a means of propellant are also being introduced. These spacecraft would be moved through space using electromagnets.

At very low temperatures, electromagnets exhibit unique behavior—once electricity is applied, they vibrate for a few nanoseconds. Researchers hypothesize that if the vibrations are contained in a single direction, the jolt could propel the spacecraft further and faster than any other propulsion method can.

Types of Thrusters Used in Space Applications

Space applications rely on the following types of thrusters:

- Field Emission Electric Propulsion: This type of propulsion relies on indium, cesium, or another metal ion. It applies a potential difference of several kilovolts between accelerator electrodes and an emitter, accelerating the ions at high speeds. Satellites use field emission electric propulsion for precision direction and altitude control.

- Gridded Ion Thruster: This is a thrust system that uses electrostatic forces to accelerate ions. Negatively charged electrodes on the thruster’s downstream end create the electric field to facilitate acceleration. Coaxial apertures on the electrode function as lenses by focusing the ions. Positively charged upstream electrodes act as an accelerator grid, which attracts the ions and creates numerous ion jets. The amount of voltage applied affects the ions’ exhaust velocity in the beam.

- High-Efficiency Multistage Plasma Thruster: THALES Electron Devices in Germany developed this thruster, based on the ion thruster principle. It consumes propellant at a rate below 20% of the chemical system. The magnetic exit cusp confines low-energy neutralizer electrons to maintain a reduced plasma potential toward the thruster end, resulting in only a few electrons reaching the discharge channel’s exit cusp. The electrons that escape get trapped along the bent magnetic flux lines in spirals. The strong magnetic field gradient acts like a mirror, reflecting electrons in a radial direction.

- Hall Effect Thruster: This thrust system depends on electrostatic potential to accelerate ions. At the thruster’s open end, plasma creates a negative charge. A radial magnetic field equal to approximately 0.03 Tesla confines the electrons, while xenon gas or other propellant is fed through an anode and diffuses into the thruster’s channel, where the electrons ionize it. The propellant ions are accelerated between the cathode and anode.

- Magneto Plasma Dynamic Thruster: Based on the principle of Lorenz Force, Magneto Plasma Dynamic Thrusters eliminate the need for fuel combustion. Xenon, argon, neon, or another gas is ionized as it is fed into the accelerator chamber. The power source creates an electric and magnetic field, and the ionized gases are propelled out of the exhaust chamber, generating thrust.

- Pulse Plasma Thruster: As the most simple electric propulsion system, the pulse plasma thruster was used in 1960s Soviet-era spacecraft. An arc sent through fuel turns into plasma, which then travels between two capacitor-charged plates, charging the plasma and creating an electron flow. A strong electromagnetic field is created, exerting Lorenz Force and exhausting the accelerated plasma at high velocities. It functions on similar principles to a railgun.

- Quad Confinement Thruster: Using eight electromagnets, quad confinement thrusters generate a convex magnetic field with a central cusp and four outer cusps on the periphery. Accelerated ions pass through a Hall Effect static field to create thrust.

Contact Custom Coils for Your Electromagnet Needs!

Many applications depend on electromagnetic propulsion, including spacecraft and military aircraft. Electromagnetic propulsion is being researched for missile launches, long-range artillery, and direct-fire tank guns. It is also an essential technology in enabling all-electric submarines and naval ships in the future.

Custom Coils has been developing, testing, and manufacturing specialty coils since 1978. We specialize in creating custom coils for challenging applications, such as vacuum, zero gravity, and extreme temperature conditions typical to the aerospace industry. Contact us or request a quote to learn more about our capabilities.

Vacuum Casting

Comments Off on Vacuum Casting

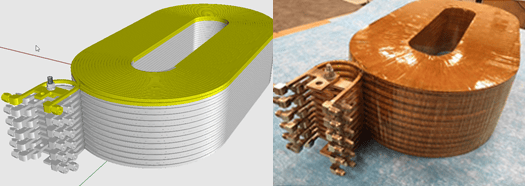

Vacuum casting of wire coils removes air from the material surrounding the windings, which results in better thermal control of the component. This process also creates specific physical geometries that enhance the structural integrity of coils and allow for better compliance with space requirements. Vacuum casting is an effective process to protect coils from humidity and contaminants and is helpful in the reduction of winding noises.

Learn more about vacuum casting, how it works, and the benefits and applications of this process.

What Is Vacuum Casting?

Also known as vacuum impregnation, vacuum casting of wire coils involves the elimination of as much air from a structure as possible while replacing it with epoxy that has higher dielectric strength. Epoxies are special adhesives that will bond the wires and other components of the construction to create a more durable assembly.

How Does Vacuum Casting Work?

The vacuum casting process utilizes a chamber capable of handling temperature, vacuum, and pressure. This manufacturing process eliminates the voids or cracks in insulation that will eventually lead to the failure of a part. In coil manufacturing, vacuum casting and impregnation play a key role in protecting coils from corrosion and enhancing their mechanical and electrical characteristics.

The vacuum casting process requires a heated chamber and involves the following steps:

- The coil is placed in a mold within the chamber and heated to remove moisture.

- Air is removed from the chamber through a vacuum process.

- Epoxy/resin is separately degassed.

- Resin is injected into the chamber, filling the mold and fully covering the windings.

- Vacuum is slowly released and the component undergoes a curing process before it is removed from the mold.

Both traditional injection molding and vacuum casting require a mold tool that contains a cavity in the shape of the desired part.

Benefits of Vacuum Casting

A single master pattern can produce many copies of a component, reducing the money and time spent on the prototyping and product design stage. Some principal benefits of vacuum casting include:

- Thermal Properties: This process improves heat dissipation and is ideal for components subject to high temperatures.

- Physical Geometries: Vacuum casting allows for greater flexibility in terms of features and shapes as well as adhering to specific space constraints.

- Improved Coil Impregnation: Compared to other methods that can contain cracks or air pockets, vacuum casting is a more precise method of creating void-free insulation.

- Improved Electrical Performance and Durability: Eliminates partial discharge and reduces winding noises.

- Suitable for Various Applications: Vacuum casting allows manufacturers to customize parts for a wide range of properties and features designed into the mold that shapes the assembly.

Applications of Vacuum Casting

Typical uses of vacuum cast coils can include but are not limited to the following applications:

- Magnetic Resonance Imaging (MRI) Coils

- Current Transformers

- High-Voltage Ignition Coils

- Voltage Transformers

Vacuum Cast Components from Custom Coils

Since 1978, Custom Coils, Inc. has provided our valued customers with design-specific, high-quality manufactured coils, electromagnets, coil assemblies, inductors, solenoids, and more.

From our 23,000-square-foot facility in Benicia, California, we fulfill our customers’ manufacturing requirements, from small or single prototype coils to large-volume coil assemblies. Everything we manufacture is designed to match our customers’ specifications, and we integrate those requirements into a unique manufacturing solution to minimize cost while maximizing quality.

Contact us for more information on our vacuum casting and other custom coil manufacturing capabilities. You can also request a quote, providing us with specific details about your project.

Multi-coil Configurations and Their Effects

Comments Off on Multi-coil Configurations and Their Effects

With almost unlimited possible multi-coil configurations, it’s important to understand how standard multi-coil configurations interact when selecting custom coil components. While the electromagnetic properties of simpler multi-coil devices are easy to predict and control, managing more complex configurations requires a thorough understanding of how fields of basic multi-coil configurations interact.

Types of Multi-coil Configurations

Electrical engineers use various multi-coil designs to model the electromagnetic field of each configuration and determine its properties. These considerations are useful to achieve specific electromagnetic effects in various devices, and the qualities of any given multi-coil greatly affect its potential applications. The following are the most common standard multi-coil configurations, along with their associated electromagnetic properties and general applications.

- Dipole Magnet: Dipole magnets are capable of producing homogeneous magnetic fields across large distances. They stimulate particle motion in a circular plane perpendicular to the electromagnetic field, which is ideal for particle accelerators. By applying multiple dipoles along the same plane (collinear to the particle trajectory), it’s possible to increasingly bend the beam’s helical direction radially.

- Helmholtz Coil Configuration: A Helmholtz coil configuration is an almost completely uniform type of dipole magnet, consisting of two coils generating equal currents along the same axis. Because they have minimal variability, Helmholtz coils are useful for applications such as calibrating scientific instruments and canceling out the Earth’s magnetic field.

- Quadrupole Magnet: Because individual quadrupoles cannot focus along both vertical and horizontal axes at the same time, each quadrupole focuses along one plane, and defocuses along a plane perpendicular to it. There are actually two types of quadrupoles:

1. F quadrupoles, which focus horizontally

2. D quadrupoles, which focus verticallyPlacing both types of quadrupoles together directly cancels out their electromagnetic fields; however, placing them at a distance leaves certain portions of each quadrupole’s field intact, resulting in unique interference patterns. It’s then possible to control both the vertical and horizontal axes within an electromagnetic lattice produced by a quadrupole pair. By carefully spacing F and D quadrupoles, the direction and range of the magnetic beam’s focus is subject to control.

These properties make a carefully configured quadrupole pair ideal for controlling beam focus and particle generation. Depending on the type of lattice built by the interference pattern, it’s possible to send particle beams across large distances, form a complete ring, and achieve other specific effects.

Applications of Multi-coil Configurations

Electromagnetic devices often require an array of multi-coil configurations to achieve the desired effect. By combining different coils, it’s possible to control an electromagnetic field with precision control. The complexities of multi-coil systems rise with the use of less standard multi-coil configurations.

For custom, specialty coil designs, it’s critical to perform comprehensive modeling of any multi-coil configuration’s electromagnetic properties. Doing so makes numerous applications possible in the safest and most effective way while reducing unwanted electromagnetic interference.

Electromagnetic Field Effects

By altering the size, power, orientation, and placement of coils in relation to each other, basic coil configurations give way to more complex electromagnetic fields. Using different multi-coil configurations is fundamental to custom coil design, electronics manufacturing, and any application where electromagnetic residue might be problematic (such as motor shafts).

To control electromagnetic fields, it’s common to begin by designing and modifying more basic multi-coil configurations and determining their effect on the resulting electromagnetic lattice, beam direction(s), and other properties. In this way, technicians can design electromagnet coil products according to the specific needs of electronics manufacturers in numerous industries.

Contact Custom Coils for your Multi-coil Configuration Needs!

While potentially very complex, the foundations of multi-coil device configurations are relatively simple. By studying the effect of each coil on the electromagnetic field, Custom Coils’ experienced engineers achieve maximum control of these properties in our custom multi-coil devices.

If you have any need for specialty multi-coil products, request a quote from our highly knowledgeable project engineers. We can help you determine which multi-coil configuration is right for your design, including fully custom solutions.