Medical professionals rely on access to high-quality preclinical imaging tools to monitor healthy and diseased tissue, make diagnoses, and develop treatment plans. Three tomographic preclinical imaging options have been available over the last few decades: positron-emission tomography (PET), computed tomography (CT), and magnetic resonance imaging (MRI).

Each has its own drawbacks, from using ionizing radiation to achieve images or lacking the capability for real-time 3D volume imaging. However, magnetic particle imaging (MPI), a new, cutting-edge preclinical imaging technology, promises to provide superior insight into our biology and diseases’ effects on it down to the molecular level.

What Is Magnetic Particle Imaging (MPI)?

MPI creates three-dimensional, finely detailed images of organs, tissues, cells, and molecular-level specimens. It utilizes specialized imaging hardware coupled with tracers of specific metal particles called super-paramagnetic iron oxides (SPIOs). Once a medical professional has introduced the tracers into the patient’s targeted systems, the patient moves to the MPI scanner’s imaging region, where they’re exposed to a magnetic field. The SPIOs interact with the equipment’s field gradient, creating detailed particle images of the examined tissue, system, or region with optimal resolution and contrast.

The Problems MPI Solves

MPI systems address two critical issues that other modern-day scanning options struggle with:

- Profusion imaging. Medical professionals run billions of dollars worth of profusion scans each year to track the flow of blood through tissue or an organ like the heart or brain. However, the images often lack the detail or resolution that would allow for early medical detection and intervention.

- Radiation and contrast agents. Scanning technology often requires the use of radioactive tracing elements and contrast agents. Patients cannot regularly be exposed to these volatile substances, so medical professionals can only take a limited number of scans, further exacerbating the risk of missed disease indicators.

Alternatively, MPI can pick up on small abnormalities, so it assists with diagnosing diseases sooner because of the superior sensitivity of the technology. Medical professionals won’t need a high volume of SPIO tracers to produce an image, and SPIOs are also safer for patients.

How MPI Works

Rather than detecting tissue itself, MPI works by tracking the movement of SPIO particles in specific tissues, organs, or areas of the body. Medical professionals can even target the application of tracers to focus on a single factor, like CAR T-cells.

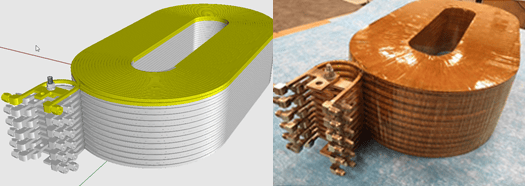

These systems have two permanent, sizable MPI magnets directed at each other, generating a strong magnetic field. However, in the middle of the MPI magnetic field, there is a field-free, or fueled-free, region (FFR) that generates little magnetic force in a known location. This field-free region will interact with any SPIO nanoparticles with which it crosses paths, making these particles flip, which the MPI receiver coil then interprets as a signal.

The MPI moves the magnetic field very quickly over the patient in the equipment’s imaging region, causing all of the SPIO particles to flip. These signals, as the technology understands them, pinpoint a specific location and MPI translates them into a quantitative, finely detailed 3D image through tracer distribution.

How MPI Differs From Other Imaging Techniques

MPI operates very differently from other imaging methods, providing a higher degree of image quality. Though they have different magnet architectures, MPI is often compared to MRI, which uses magnets to identify resonance from the H nucleus and other nuclear spins. MRI technology has common applications in anatomical imaging but doesn’t provide the same fine-tuned imaging on a small scale that MPI can.

Rather than picking up on nuclear signals, MPI detects nanoparticles’ magnetization, allowing for a much greater degree of sensitivity and better success in cellular imaging tasks. Compared to PET imaging and MRIs, MPI is also a faster imaging option.

Applications of MPI

With various uses in the medical sector, key MPI applications include:

- Early cancer, cerebrovascular, and cardiovascular disease detection. With sub-micromolar sensitivity, MPI doesn’t have to use radiation but can still achieve reliable screening results for earlier, better illness detection.

- Perfusion imaging of the heart. Similarly, its sensitivity allows healthcare professionals to receive enhanced heart images for better evaluation.

- Monitoring treatment progress. Given its spatial and temporal resolution capabilities with a zero background signal for endogenous tissue, use of long circulation half-life particulate, and speedy access, MPI is adept at monitoring ongoing treatments.

Benefits of MPI

MPI is particularly advantageous because of its superior sensitivity, speed, and safety compared to other imaging options. It doesn’t rely on radiation like PET or x-rays like CT, so it makes more frequent screenings possible. Also, the system is easy to operate, even without dedicated personnel, so medical researchers can gather data on their own.

Most importantly, MPI produces industry-best, high-resolution images that can dramatically improve early detection, diagnosis, and treatment development. It has the potential to one day scale from preclinical to clinical applications as an alternative to radiation-using PET and SPECT scans.

Custom Coils Provides Magnetic Coils for the Medical Industry

Coils and electromagnetic assemblies are critical to the efficiency and dependability of advanced imaging and scanning technologies. Our expert team works with companies in the demanding medical and research areas of this sector to create high-quality, industry-compliant coils, inductors, and electromagnets. We understand that, particularly in critical industries, there is no one-size-fits-all solution, and so we draw on decades of experience to collaborate with you and find the material and design that will ensure accuracy and longevity in your product. Contact us to learn more about our capabilities for your components’ full development cycle, or request a quote today for pricing details.