In addition to MRI systems, RF coils play a key role in semiconductor, telecommunications, and aerospace applications. Custom Coils specializes in designing and manufacturing high-quality RF coils tailored for specific applications and requirements. Our coils improve imaging quality and enhance sensitivity in targeted areas.

Learn more about working with us for your RF coil assembly needs.

Custom Coils: Your Partner in Innovation

Custom Coils prioritizes innovation and customer-centric solutions throughout the project lifecycle. We craft RF coil assemblies to your exact specifications, integrating your requirements into a unique manufacturing process solution that maximizes quality while minimizing costs.

Our partnership doesn’t end after a single project. We focus on building a long-term relationship and offering ongoing support for your current and future projects.

Design and Engineering Excellence

At Custom Coils, we pride ourselves on our design and engineering prowess. For every RF coil assembly, we gather design inputs and requirements from the client, using this information to confirm the design or make recommended changes. After multiple rounds of review, the client approves the final design, which specifies:

- Turn count

- Resistance / inductance / power data

- Conductor selection

- Lead orientation and terminations

- Cooling components, if any

- Finishing requirements

- Physical/mechanical constraints of the equipment

- And more

We design and engineer every custom RF coil for optimal manufacturability, ensuring the high quality and repeatability of the coil during production. This also helps reduce costs for the customer.

Prototyping Services

Our rapid prototyping services involve rigorous testing, validation, and iterative development, with an emphasis on client collaboration. We also perform various quality control processes, such as visual inspections, tooling fabrication, thermal modeling, pressure testing, and more. Throughout the process, we suggest design improvements to improve quality, cost, and manufacturability.

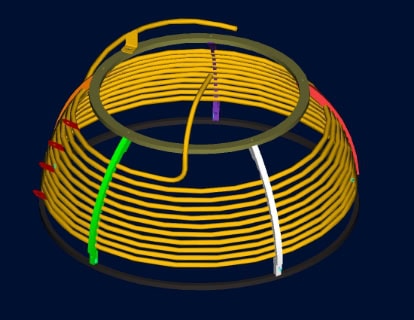

Advanced Manufacturing Capabilities

Our unique winding procedures and state-of-the-art manufacturing technologies are at the heart of our operations. Custom Coils specializes in producing high-quality, repeatable manufacturing processes for unique coil projects. Whether it’s a small batch or large-scale production, our scalability ensures that your needs are met with precision and efficiency.

Quality Assurance and Certifications

At Custom Coils, our comprehensive quality control measures include:

- 100% part/process tracking

- First Article Testing

- Thermal modeling

- Tooling design and fabrication

- Magnet specification designs

- Pressure testing

- Rigorous visual inspections

- Electrical and dimensional testing

To deliver the highest-quality coil assemblies that comply with your industry’s regulations, we adhere to certifications and standards like UL, NEMA, ISO 9001:2015, and ISO 13485:2016. At Custom Coils, every RF coil assembly demonstrates our commitment to producing high-performance, reliable products.

Get Started with Custom Coils

RF coils are essential to the proper function of critical medical equipment, such as MRI systems. Partnering with Custom Coils means you’ll get a custom coil assembly that meets your exact specifications. Contact Custom Coils or request a quote today to get started on your custom RF coil assembly.