Materials Used for Inductors

The type of inductor determines the materials used as well as the manufacturing method. Wire wound inductors rely on a core made of ferrite, non-magnetic plastic, or ceramic with a coil wound and soldered around it. Power supplies and general applications use ferrite, while radio-frequency applications rely on a non-magnetic material. Manufacturers machine a frame, mount the inductor to it, and coat the inductor in a molded resin. The frame forms the terminal electrodes.

Another category includes thin-film inductors much like semiconductors. They print thin-film coils onto a substrate made from magnetic metal, such as ferrite or alumina. The substrate is cut to meet the specified chip size, and the thin film inductor is formed by shaping and plating the terminal electrode.

Manufacturing layered inductors is possible using thick film printing or the more common sheet printing method. Sheet printing begins with preparing the multilayer sheets. Manufacturers fabricate a via hole and print an internal conductor pattern before forming the sheet layer. They cut and sinter the chip, then apply the terminal electrode and electroplate the inductor. Typically, ceramic is chosen for high-frequency applications, while general-purpose and power supply inductors use ferrite.

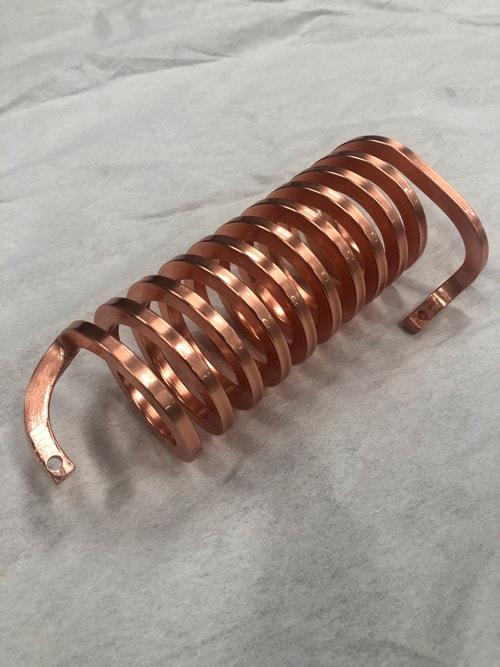

Inductors From Custom Coils

At Custom Coils, we manufacture inductors and chokes to suit a range of applications. We specialize in coils for high power and thermal applications and deliver prototypes and production runs in small to large volumes.

We design and manufacture several coil products, including air cores, bobbin wound cores, chokes, and inductors of various types and materials. Our products use 100% trackable parts and meet ISO, NEMA, and UL standards. We can also test for factors like surge and mechanical capabilities, and we offer a range of secondary manufacturing services.

Contact us to learn more about our custom inductor manufacturing capabilities or request a quote today.