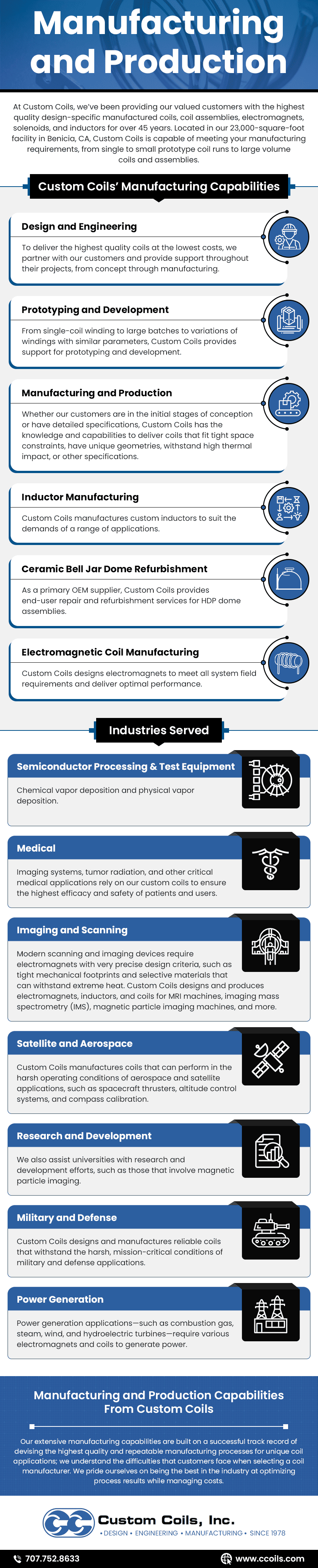

At Custom Coils, we’ve been providing our valued customers with the highest quality design-specific manufactured coils, coil assemblies, electromagnets, solenoids, and inductors for over 45 years. Located in our 23,000-square-foot facility in Benicia, CA, Custom Coils is capable of meeting your manufacturing requirements, from single or small prototype coils runs to large volume coils and assemblies.

Our Manufacturing Process

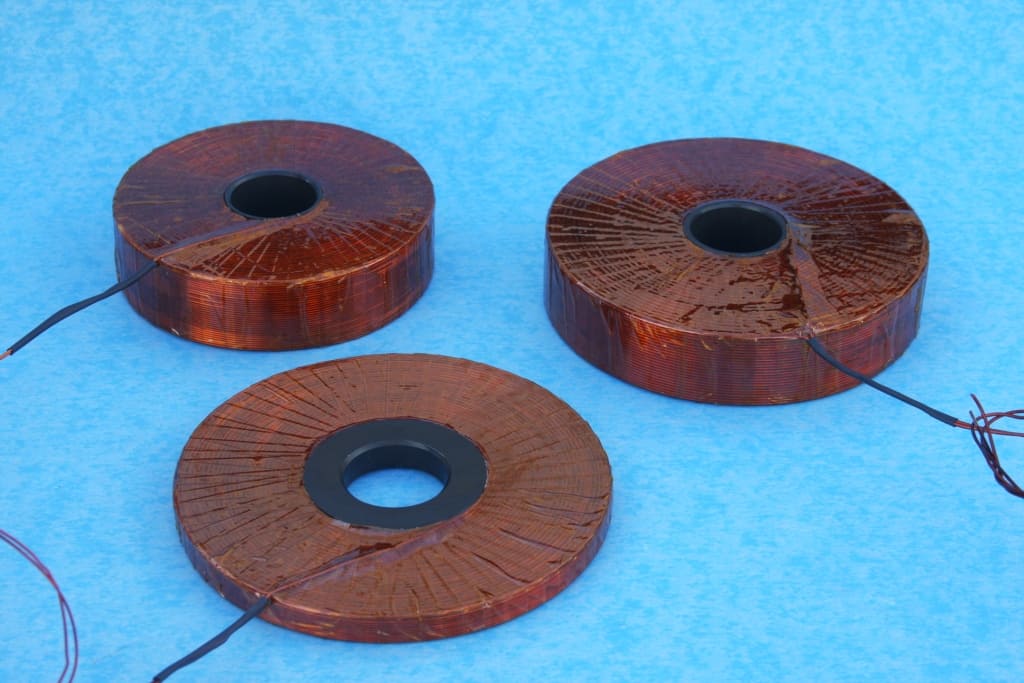

We manufacture custom coils using our unique winding procedure, where ultra-fine wires commonly made of copper or aluminum are twisted around a core or pin in a round, helical, or spherical configuration. Because of the different applications of custom coils, the shapes and sizes of the coils will vary. To manufacture coils with different thicknesses, we alter the number of windings around the core. Coreless coils are manufactured by removing the core after the winding process is completed.

As a custom coil manufacturer, Custom Coils partners with customers through the entire production life cycle, from initial design to product development, testing, and production release. We offer:

- Custom Design Services for Production Quality and Efficiency

- Material Specification Consulting

- Coil Modeling and Analysis

- Thermal Modeling and Analysis

- Design for Manufacturability Analysis

- Full Electrical and Mechanical Capabilities

We have the knowledge and resources needed to design and manufacture quality coils that meet any system requirement.