No matter how demanding your component requirements, we have the resources available and experience needed to ensure your project is a success. Since we serve many customers from many industries, and have over 5000 part numbers in our production database, we have the knowledge and experience to source an extensive range of coil materials. Our team can help you develop the most cost-effective design, sourced with materials which can withstand even the harshest operating environments.

Material Selection and Procurement Services

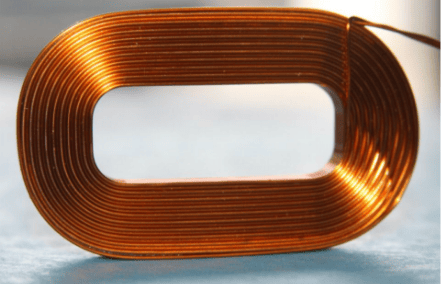

At Custom Coils, our team brings over 30 years of design and manufacturing expertise to custom electromagnetic assemblies. Using our extensive knowledge of coil materials, we work closely with our clients to develop custom solutions and build products that maximize their design objectives. Since many of the projects, with which we work, are used in high power applications, the proper selection and specification of materials is critical to ensuring performance optimization and component longevity.

Material Selection

Perhaps no design consideration is more critical to ensuring the highest quality and reliability of an electromagnetic than the selection of materials. With every design application, there exists a unique combination of materials necessary to optimize product reliability and cost. We can help you optimize your electromagnetic component by offering a wide array of material options that will meet the output requirements, at the most reasonable cost.

Design & Engineering

Our engineers are available to answer all questions and support any challenge relating to the design of your project. Our team will ensure all industry-specific standards and regulations are met as well as any unique design needs you require. We work with simple and complex designs, including those with high thermal challenges, unusual mechanical cross sections, tight space constraints, and extensive testing requirements.

Prototyping & Development

Prototyping and product development are crucial aspects of coil production. We thoroughly test in-progress configurations to identify areas for further design improvements. No matter how large or small your project is, we will optimize your designs for quality, manufacturability, and cost.