Electromagnets and electromagnetic devices generate heat primarily due to electrical resistance in their windings and magnetic losses in their cores. As current flows through the conductors, resistive (I²R) losses convert electrical energy into heat. Additional heat can come from eddy currents and hysteresis within magnetic materials. Without proper thermal management, this buildup of heat can reduce field strength, affect stability, and diminish overall performance. Effective cooling and heat dissipation allow these systems to operate reliably at or near room temperature.

Cooling systems can even make electromagnets create stronger fields. At Custom Coils, we design and develop custom electromagnetic coil assemblies, including thermal management materials, to ensure proper performance and heat management during short-term and sustained applications. With extensive experience in thermally challenging applications, our team has identified a wide range of component materials that optimize heat dissipation and support superior thermal management across diverse operating conditions.

How Heat Affects Electromagnets

Electromagnets rely on the proper flow of electrical energy to power the magnetic field at the right strength. Average hot temperatures only lead to a slight drop in electricity flow, but if the wire coil overheats, it loses more conductivity and generates a weaker magnetic field. The electricity vibrates more in the wire instead of moving steadily on track, and this added resistance leads to lower performance.

At very cold temperatures, electromagnets can create a stronger field with less electricity. To prevent potential damage and downtime from overheated electromagnets, investing in these cooling methods can improve your operational efficiency and keep the electromagnets functioning reliably for longer.

Types of Cooling Methods

Cooling electromagnets reduces the excess vibration of electricity as it runs through wire coils. But there are many different cooling mechanisms and specific product assemblies that can lower operating temperatures and improve energy flow. At Custom Coils, we frequently work with three main types of cooling: air cooling, liquid cooling, and hollow conductors.

Air Cooling

One of the most common ways to regulate heat is with fans that circulate air. Air cooling can restore electromagnetic coils to room temperature. Fan-based air cooling processes pull heated air away from electromagnetic assemblies and push in cooled air. Advanced air cooling methods also include using a flow of gaseous nitrogen (N2) at room temperature or gaseous nitrogen pre-cooled by liquid nitrogen (LN2).

Liquid Cooling (Nitrogen, Helium)

To achieve optimal performance levels at very low temperatures, electromagnets can also be cooled using liquid cooling, specifically liquid nitrogen or helium. These methods ensure that electricity can run smoothly and efficiently through coils to produce a strong magnetic field:

- Liquid helium. Liquid helium baths cool electromagnets at very low temperatures (-270 °C). Liquid helium cooling is typically used in MRI scanners to create high-resolution imaging.

- Liquid nitrogen. Liquid nitrogen cools electromagnets at -196 °C. Operators often use liquid nitrogen either as an insulator to keep liquid helium in a liquid state or as a pre-cooling agent.

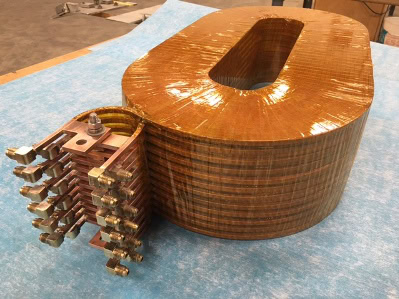

Hollow Conductors

Hollow conductors have a hollow core with low-conductivity water flowing through them. Compared to conventional solid conductors, hollow conductors can facilitate very high magnetic fields. They also don’t generate and hold heat the same way as solid core coils, allowing for more effective thermal management.

Contact Custom Coils for Expert Guidance

Custom Coils offers versatile custom electromagnetic coil designs and hardware, including thermal management of electronics to prevent overheating. Our technicians comply with ISO, MIL-SPEC, RoHS, aerospace, and medical standards to ensure proper performance and reliability in critical applications. Custom Coils partners with our clients to explore different coil arrays, thermal management materials, and configurations to produce superior results. We can develop custom-engineered coils that meet exacting specifications and can accommodate prototyping and small-batch production runs for R&D.

Contact us today to learn more about our custom coil design and production capabilities, or request a quote for pricing details.