RF Inductor Basics

Comments Off on RF Inductor BasicsRadiofrequency (RF) inductors are critical electronic components in applications from consumer products to complex scientific equipment. RF inductors perform numerous functions in high-frequency circuit applications, such as high-frequency chokes, filtering, impedance matching, and circuit tuning. These inductors are prevalent in modern technology, including IoT devices, wireless devices like tablets, and specialized applications such as testing equipment and GPS.

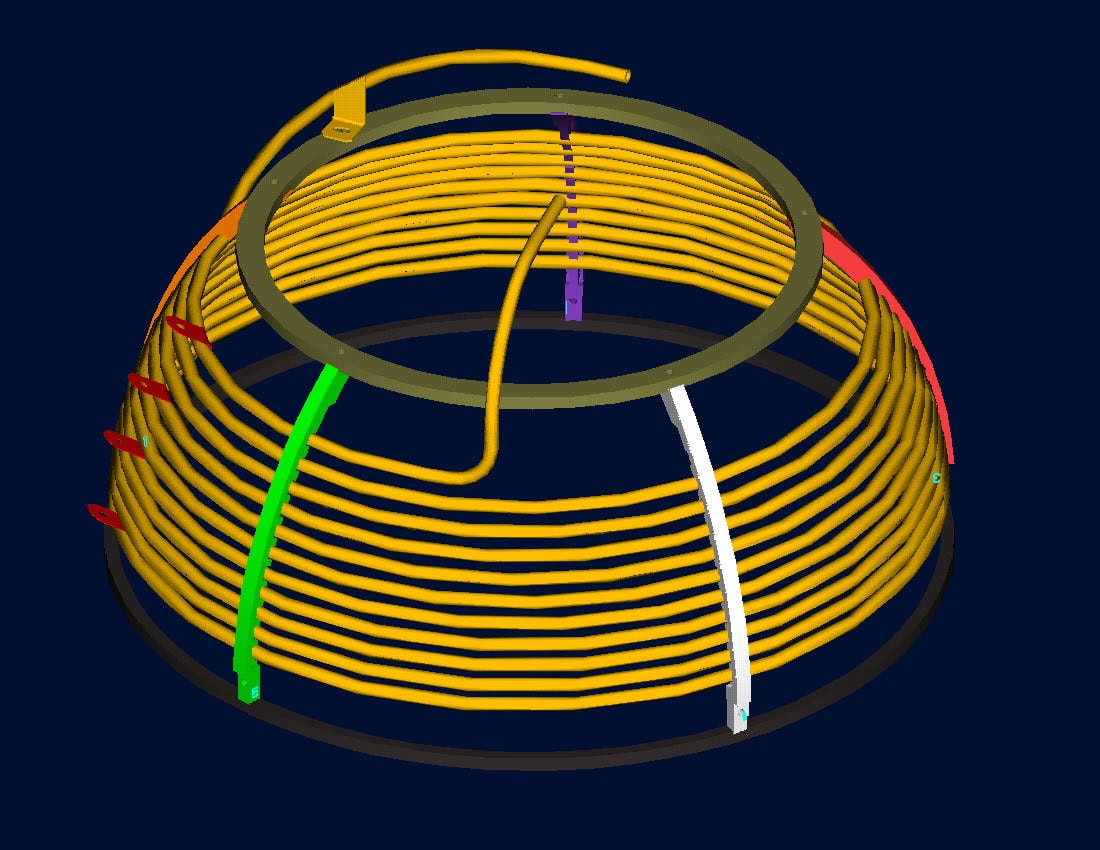

What Is an RF Inductor?

RF inductors are passive components that oppose sudden variations in electrical currents. Sometimes called chokes or coils, inductors are symbolized by an L on electrical documentation. When an electrical current flows through an RF inductor, the energy is stored in an electromagnetic field. Ideal for high-frequency electrical applications, RF inductors provide the following functions:

- Impedance of Current Changes: An inductor installed inline or in series with a circuit board trace or wire impedes current changes, like AC noise, by storing the energy temporarily in its magnetic field before re-releasing it into the circuit.

- Energy Storage and Voltage Creation: As the current traveling through the RF inductor varies over time, the energy in the inductor’s magnetic field produces an opposing voltage to impede the current from changing further.

- Opposing Current Changes: The magnetic field slows the rate of change as the current passes through the inductor, regardless of whether it is decreasing or increasing. RF inductors work like shock absorbers dampening mechanical energy, dispersing electrical energy spikes or current noise that would otherwise damage the system.

Characteristics of RF Inductors

RF inductors work like other inductors, governed by the same rules of physics as power inductors. They are characterized in the same terms, with parameters like inductance, permeability, and turns. These similarities allow RF inductors to use the same formulas as conventional power inductors. RF inductors also share similar parameter ranges in their datasheets, including those for rated current, DC resistance, inductance, and tolerance.

However, RF inductors also have a quality factor that is crucial to validating the inductor for performance in a specific application. Here is an overview of all the basic parameters to consider when selecting or specifying an RF inductor:

- Inductance Value and Tolerance: Inductance is the most important parameter of RF inductors. Similar to conventional power inductors, it is defined by the core’s relative permeability, the core’s cross-section, the core’s effective magnetic path length, and the number of turns around the core. RF inductors require a design with high inductance stability, flat inductance curves, and tight tolerances. Tight tolerances ensure the inductance value is as close to the nominal value as possible for impedance-matching applications, oscillator circuits, and high-order filters.

- Self-Resonant Frequency (SRF): Constant inductance at the relevant frequency range is vital in impedance-matching and filter applications, meaning the inductor’s SRF must be well above the circuit’s operating frequency.

- Quality Factor (Q): The inductor quality factor, or Q factor, is the ratio between reactance (XL) and losses (RS) and can indicate the ideal performance of an inductor for an application. Inductors with high Q offer low dissipation and can make finely tuned narrow-band circuits. Low Q inductors offer wideband performance with higher dissipation.

RF Inductors From Custom Coils

RF inductors are electrical components that impede and control currents flowing through them by storing the energy in an electromagnetic field, releasing the current at a controlled rate, and reducing noise. In RF inductor selection, many factors are identical to conventional power inductors. However, engineers also must review the quality factor of the RF inductor to verify if it is a good fit for their application. Custom Coils can help you select the ideal RF inductor for your application with our design and manufacturing experience.

Custom Coils has manufactured chokes and inductors for various applications since 1978. Our facility is ISO 9001:2015 and ISO 13485:2016 certified to ensure quality processes and products. We specialize in designing and manufacturing custom coils for thermal and high-power applications. Our full production cycle services include developing prototypes, small- to large-volume production, testing, and more.

Contact us or request a quote to connect with a specialist about your inductor or coil needs.