Since electromagnetic coils are critical components used in many industrial applications, the coils must meet the varied demands of each one. The following are some of the most common types of electromagnetic coils and how they’re used.

Custom Coils Inc. designs and manufactures custom specialty coils for a variety of industries and applications. For even the most challenging projects, our experts can deliver high-quality design conceptualization, prototype development, testing, and production. This page will explain how electromagnetic coils work, their different types and applications, and important design considerations when creating custom solutions.

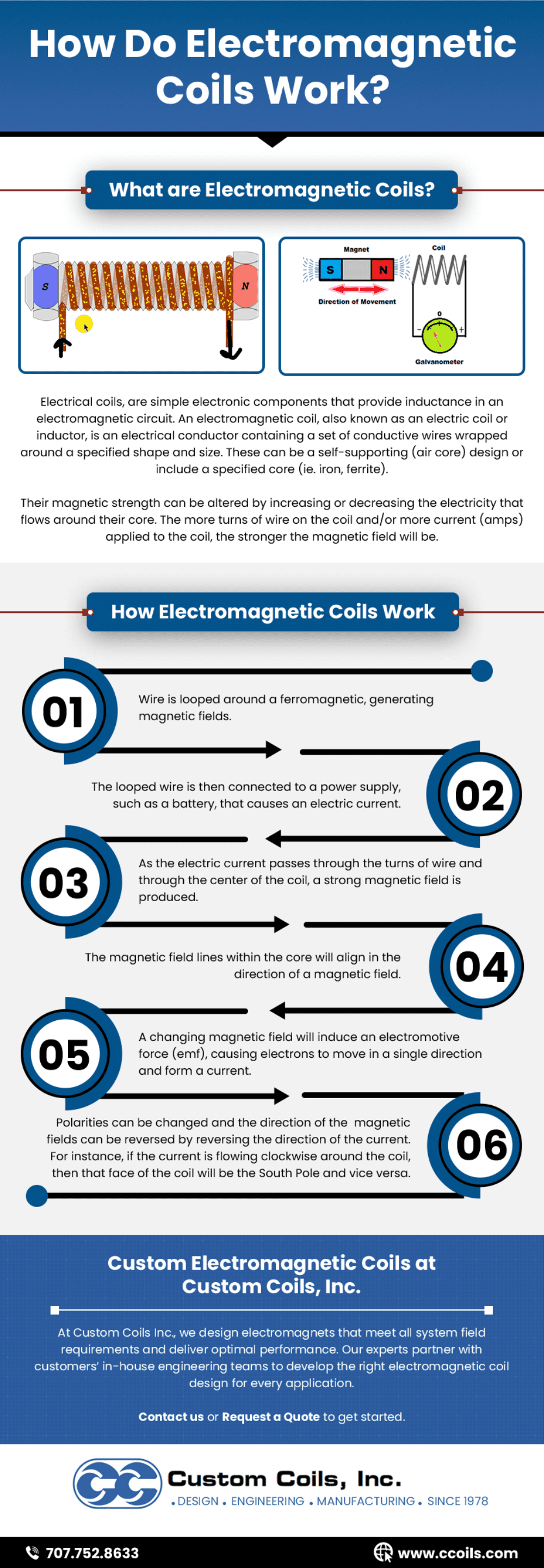

Anatomy of An Electromagnetic Coil

Click on the different parts of the coil depicted below to learn more about the anatomy of a coil and the significance of each part.

1.Thermal Management

Often dimensional constraints and operational requirements of the electromagnet produce a coil that will heat up beyond temperature limits of the materials or system it is operating in. Additional cooling may be required to draw heat out of the coil. This is copper tube cooling which can be applied on the ID, OD, or in the center of the coil windings.

2.Epoxy/Binder

An epoxy/binder is used to support and set the coils windings and acts as an insulator so that the coil can withstand extreme environmental conditions like high temperature. An epoxy impregnated finish increases dielectric strength, reduces partial discharge, and also provides good thermal conductivity.

3.Conductor

Typically copper with an outer insulation, the choice of conductor is integral to the design of the coil, defining the main properties of the electromagnet, including number of turns, magnetic field, resistance, power, and dimensions. Magnet wire is available in many forms and constructions.

4.External Insulation

Often external insulation is required to isolate the coil assembly from the environment or as ground protection from other areas of the assembled system. External insulation can take the form of a casting or encapsulation, tape wrap, such as Nomex, Mylar, or Telflon, or an insulating paper such as Nomex or DMD

5.Temperature Cut off switch

Thermal sensors applied to a coil to monitor temperature and control operation when a coil gets too hot or rises beyond operational limits.

6.Lead with/termination

Coil lead routing and power requirements are an important and often overlooked part of the design. Contact Us to discuss the many design and material options for how to power your coil.

Custom Electromagnetic Coils at Custom Coils, Inc.

At Custom Coils Inc., we design electromagnets that meet all system field requirements and deliver optimal performance. Our experts partner with customers’ in-house engineering teams to develop the right electromagnetic coil design for every application.

What are Electromagnetic Coils?

An electromagnetic coil, also known as an electric coil or inductor, is an electrical conductor containing a set of conductive wires wrapped around a specified shape and size. This can be a self-supporting (air core) design or include a specified core (ie. iron, ferrite) . Electrical coils are simple electronic components that provide inductance in an electromagnetic circuit.

There are many coil types to meet the needs of various equipment. Electromagnetic coils can vary by wire gauge, length, coil diameter, core material, and other factors. Since electromagnetic coils are powered by electricity, they can be turned on and off easily. Their magnetic strength can be altered by increasing or decreasing the electricity that flows around their core.

How Do Electromagnetic Coils Work?

Electromagnetic coils consist of conductive wire wrapped in a specific size and shape, producing a magnetic field. The magnetic field grows stronger when there are more turns of wire on the coil. Electromagnetic field strength is determined by the number of amp turns, the material selection of the core, and the strength of current. Removing electrical input disables the magnet.

When added to a wire coil, certain core materials can increase the strength of the magnetic field. Ferromagnetic materials—cobalt, nickel, iron, and steel—can amplify a denser magnetic field for the coil.

Types of Electromagnetic Coils

- Automotive electric coils: Ignition coils in automobiles typically consist of two sets of copper wires wrapped around an iron core. The primary winding is a heavy wire, while the secondary wire is smaller and lighter.

- Energy electric coils: These coils must be engineered to withstand harsh environmental conditions in remote locations.

- Electronic electric coils: Made from finely wound wire, coils for electronic devices are in high demand. Circuit board coils go into laminated transformers.

- Electric guitar electric coils: The single coil design is the most popular form of electric guitar coil, but another form is the double coil, which helps cancel out interference.

- Medical electric coils: Coils in medical equipment, such as Radiation Therapy Systems, must be reliable. These typically high power applications require very precise process and testing procedures.

- Military electric coils: Like medical coils, military coils must be accurate and reliable. They must also be able to perform in harsh conditions. These coils are commonly used in guidance systems, sensors, and navigation systems.

- Transportation electric coils: Railroad tracks, armatures, and signaling devices all use these coils, which can withstand the constant vibrations that occur in these environments.

- Wind-powered generator electric coils: These coils must withstand temperatures up to 200 °C. They are made from lightweight materials and insulated for added protection.

- Flowmeter electric coils: Used to measure the volume of liquid or gas going through a pipe, flowmeter coils must match the radius of the pipe.

- Traffic light sensor electric coils: Inductance meters attach to these coils and change when a car enters its field, alerting the traffic light of the car’s presence.

- Transformer electric coils: Transformers utilize multiple coils to conduct electricity, with primary windings on one side and secondary windings on the opposing side.

- Linear Accelerators coils: Electromagnets (Dipole magnets) are used extensively for beam guiding and bending to move charged particles where they need to go.

Electromagnetic Coil Applications

Electromagnetic coils vary in size, shape, and material depending on their application. While there are many industries that use electromagnetic coils, three industries in particular rely on coils for critical applications.

Medical

Electromagnetic components are vital to many types of medical equipment, including heart rate monitors, Radiation therapy systems, MRI systems and more. Diagnostic equipment—such as electrocardiogram (EKG) and electroencephalogram (ECG) machines—also require electromagnetic coils.

Military

The military depends on electromagnetic coils for missile defense, protecting allied signals, and jamming enemy signals. Electromagnetic coils also apply to high-velocity electromagnetic rail guns.

Aerospace

Aerospace applications for transformers, inductors, and other electromagnetic parts must be highly precise and adhere to stringent guidelines. Electromagnetic aircraft launch systems, for example, must successfully launch aircraft from carriers.