Overview of Electromagnets

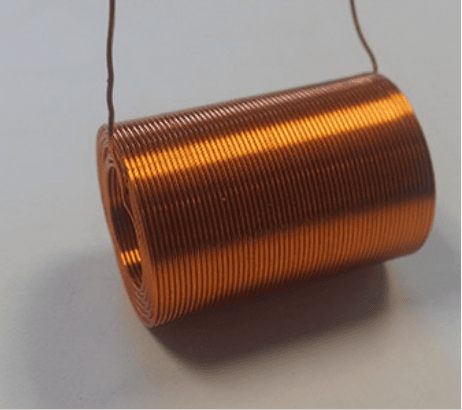

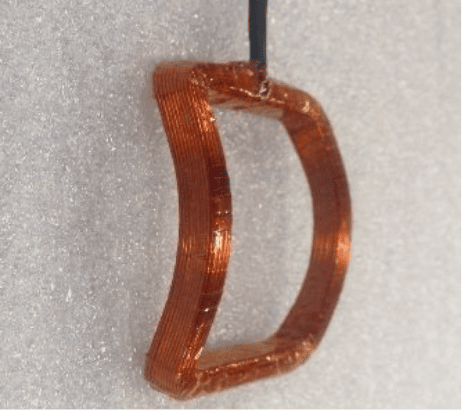

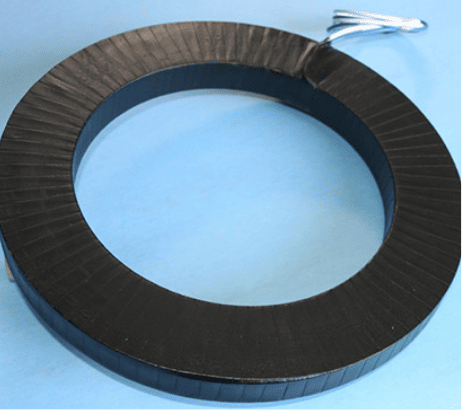

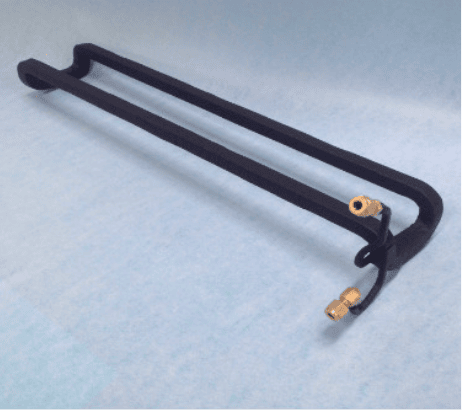

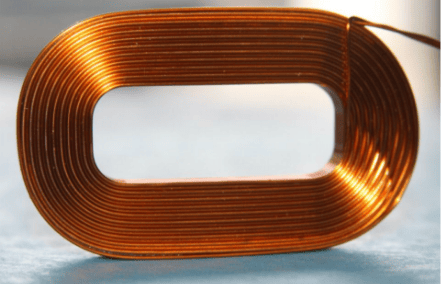

Electromagnets are a type of magnet that uses an electric current to produce its magnetic field. They are made with conductive materials, configured in varying shapes with a specified number of turns. When an electric current is turned on, it passes through the coiled wire and creates a magnetic field. When electricity is turned off, this circuit is interrupted and the magnetic field disappears.

Increasing the amount of electric current will increase the electromagnetic field strength. Varying the direction of the current will change the magnet’s polarity. Since they create a magnetic field temporarily, electromagnets are used in many applications that only require magnetic force for a short amount of time, such as in MRI machines, motors, and generators.

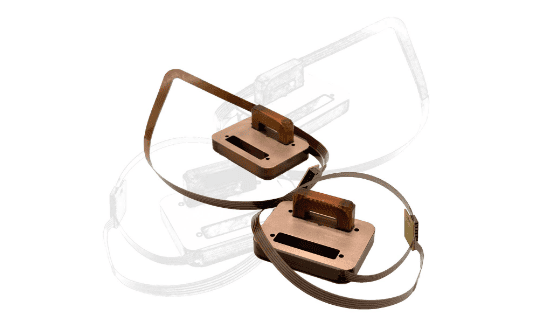

At Custom Coils, we’ve created custom electromagnets for applications throughout numerous industries, including medical imaging and scanning technology, semiconductor processing, and plasma ionization tools for dielectric etching. Electromagnetics are typically the critical components to its specific application. As such, the unique design specification, in large part, is the determining factor behind the application output and performance,

Custom Coils manufacturers specialty coils, coil assemblies, solenoids and a variety of electro-magnetic and inductive devices from limited runs to high volume production.

Turnkey Electromagnet Manufacturing

Custom Coils provides support for any part of the electromagnet development process, from creating an initial design to production. Our services are completely tailored to your needs, ensuring your project receives just the right level of support. We assist with:

INITIAL CONSULTATION AND ELECTROMAGNET DESIGN REQUIREMENTS

We take a collaborative approach to electromagnet design and work alongside your team to gain a thorough understanding of your specific design requirements.

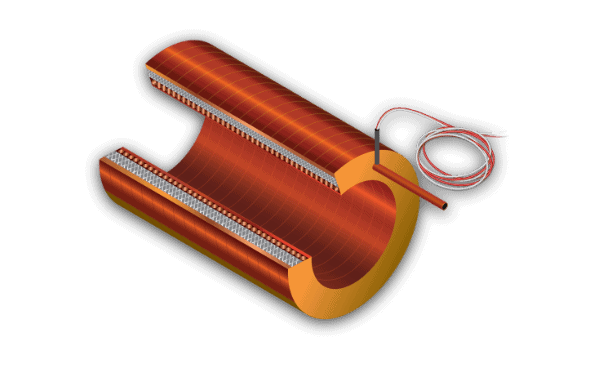

ELECTROMAGNET DESIGN AND ENGINEERING SERVICES:

Based on your optimal performance criteria, our experts carefully select the most suitable materials, design for manufacturability, and create CAD/thermal models of your design.

PROTOTYPE DEVELOPMENT:

Upon completion of design validation, a prototype plan is presented. At this time, our engineers work closely with project managers to transition to small scale production.

READ MORETESTING AND QUALITY ASSURANCE:

We offer comprehensive testing services for electromagnets, including magnetic field tests, inductance, resistance, hipot (high potential), and thermal testing. We perform full first article

READ MOREPROJECT MANAGEMENT:

Our team offers full project management services, tailored to your exact needs. We handle everything from design review to quality assessment.