A solenoid is a type of electromagnet consisting of coiled copper wire wound tightly into a helix, a mobile plunger made of magnetic material, and an iron or steel housing. As electric current moves through a coil, the solenoid generates a magnetic field and proceeds to transform magnetic energy into mechanical motion. It does this through electromagnetic forces.

For example, solenoids are often used as a valve to actuate a push or pull force on a magnetic component in a device. Solenoids can also act as a switch in electromechanical devices. These electromagnetic devices are used in hundreds of everyday applications, from doorbells to car ignition systems.

Custom Coils designs and develops quality solenoids to meet the needs of your application. We work efficiently and expertly to create specialty coils for our valued customers.

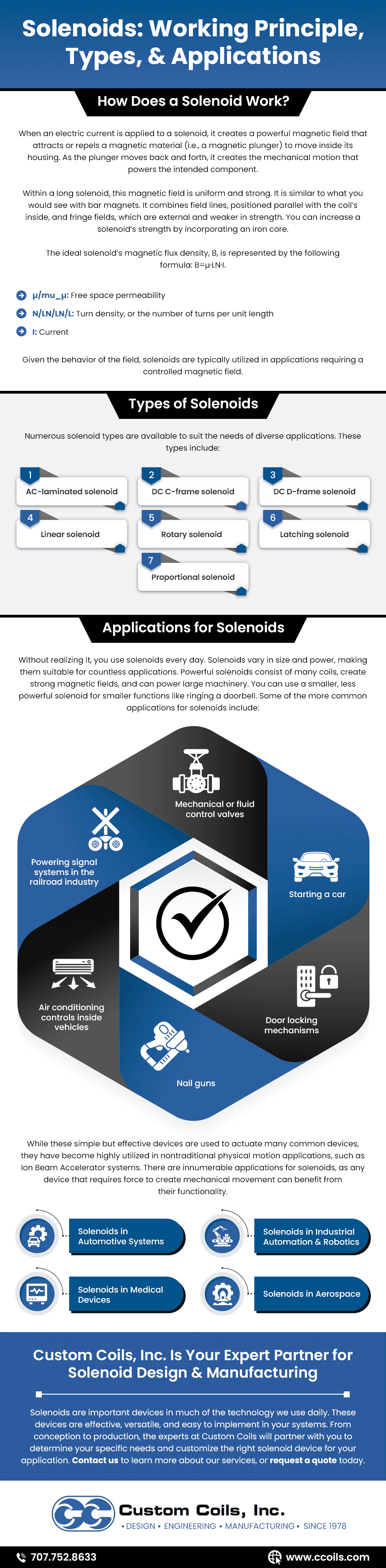

How Does a Solenoid Work?

When an electric current is applied to a solenoid, it creates a powerful magnetic field that attracts or repels a magnetic material (i.e., a magnetic plunger) to move inside its housing. As the plunger moves back and forth, it creates the mechanical motion that powers the intended component.

Within a long solenoid, this magnetic field is uniform and strong. It is similar to what you would see with bar magnets. It combines field lines, positioned parallel with the coil’s inside, and fringe fields, which are external and weaker in strength. You can increase a solenoid’s strength by incorporating an iron core.

The ideal solenoid’s magnetic flux density, B, is represented by the following formula: B=μ·LN·I.

- μ/mu_μ: Free space permeability

- N/LN/LN/L: Turn density, or the number of turns per unit length

- I: Current

Given the behavior of the field, solenoids are typically utilized in applications requiring a controlled magnetic field.

Solenoid magnets have an advantage over conventional permanent magnets because their magnetism can be switched on or off — or altered — as needed by removing or applying varying levels of electrical current. You can adjust the strength of the magnetic pull by increasing or decreasing the electrical current. Additionally, you can reverse the direction of motion based on the direction of current flow through the solenoid.

There are two basic types of solenoids: valve and electric. In valve solenoids, a constant electric current is applied to the solenoid. Once activated, the piston or plunger retracts to open the valve that would otherwise block the flow of material. Once the electromagnetic field is broken, the solenoid is deactivated and the valve will close.

Electric solenoids close circuits to allow engines to run. When the solenoid receives the electric current, it pulls nearby metal components in place to create a closed circuit. Constant electric current is required to keep the circuit closed and the engine running.

Types of Solenoids

Numerous solenoid types are available to suit the needs of diverse applications. These types include:

- AC-laminated solenoid: This solenoid comprises a wire coil and a metal core made with laminated metal, which helps reduce stray currents and optimizes the solenoid’s performance. An AC-laminated solenoid has an inrush current, which delivers a greater amount of force in the initial stroke. This also means it can deliver more strokes than DC-laminated solenoids. Common applications of an AC-laminated solenoid include locks, medical devices, industrial equipment, vehicles, and other equipment that needs immediate operation.

- DC C-frame solenoid: Some applications may also use a DC C-frame solenoid, which features a C-shaped frame that wraps around the wire coil. Suitable for many everyday applications ranging from gaming equipment and coin counters to scanners, camera shutters, and circuit breakers, this solenoid utilizes a stroke operation with excellent control. While it has a DC configuration, a solenoid of this type is actually AC power equipment compatible.

- DC D-frame solenoid: Like C-frame solenoids, the DC D-frame solenoid operates with more controlled strokes and is compatible with AC power applications. The main difference is that the D-shaped frame is made with two joined pieces that shield the coil. ATMs, gaming machines, and gas- and blood-analyzing equipment often use this solenoid type.

- Linear solenoid: This is one of the most widely recognized solenoids. A linear solenoid features a coil-wrapped metal core, delivering pushing or pulling force to operate a piece of equipment. This operation makes it popular for vehicle ignition systems and other such starting devices, as well as electric locks that allow locked vehicle doors to withstand significant force.

- Rotary solenoid: If an application needs a simple automatic control process, it may use a rotary solenoid, which has the same essential components as other solenoids but with a unique mode of operation. A rotary solenoid uses a metal core located on a grooved disc to function. The size of the grooves is based on slots on the body of the rotary solenoid, and ball bearings facilitate and streamline motion. When it is powered on, the core draws back within the body while the disc core turns. When turned off, a spring forces the disc core into its original position. A more robust solenoid variety, the rotary solenoid has common applications in industrial tasks like automated lasers and shutters.

- Latching solenoid: This solenoid type features a permanent magnet as well as a spring or related component to enable return force. Using just a brief excitation pulse, the latching solenoid will alter its end position. In the holding condition, it exhibits zero power or heat dissipation, so it is a good choice for temperature-sensitive applications. It is also compatible with systems that have minimal supply power because, at either end position, there is no power consumption. A latching solenoid is not, however, a good option for failsafe applications should a power failure occur.

- Proportional solenoid: A type of advanced linear actuator, a proportional solenoid generates force that is proportionate to the amount of excitation current an application applies. This solenoid can, when a return spring is included in its construction, serve as a positioning device. Generally, it is utilized for position, flow control, tension, and force, and the proportional solenoid has common applications in hydraulic control systems, robotic systems, textile systems, and valves.

Applications for Solenoids

Without realizing it, you use solenoids every day. Solenoids vary in size and power, making them suitable for countless applications. Powerful solenoids consist of many coils, create strong magnetic fields, and can power large machinery. You can use a smaller, less powerful solenoid for smaller functions like ringing a doorbell. Some of the more common applications for solenoids include:

- Mechanical or fluid control valves

- Starting a car

- Door locking mechanisms

- Nail guns

- Air conditioning controls inside vehicles

- Powering signal systems in the railroad industry

While these simple but effective devices are used to actuate many common devices, they have become highly utilized in nontraditional physical motion applications, such as Ion Beam Accelerator systems. There are innumerable applications for solenoids, as any device that requires force to create mechanical movement can benefit from their functionality.

Solenoids in Automotive Systems

In automotive systems, the primary function of a solenoid is to carry electrical current from a car battery to the ignition system, as discussed. Typically, vehicles will have mounted solenoids on the starter motor or related starter components. Others might have them installed in another location within the engine compartment. Automotive manufacturers will often use latching or proportional solenoids, as two examples, for internal combustion engine and electric vehicle systems. Solenoid valves, additionally, play a role in fuel injection, transmission, and emission control systems.

Solenoids in Industrial Automation & Robotics

Within the industrial automation and robotics fields, solenoid-powered valves assist users in managing simple to complex pneumatic and hydraulic fluid flow within a system or piece of machinery. For example, they’re applicable for process control systems, conveyance systems, and equipment like actuators and robotic arms, in which they control actuator movement with great precision. Essentially, solenoids promote efficiency, dependability, safety, heightened speed, and overall operational improvements.

Solenoids in Medical Devices

Rotary and linear solenoids are good options for medical device applications. In equipment for medication dosing, dialysis, and monitoring blood pressure, these solenoids enable a high degree of force and stroke accuracy and reliability. This better allows medical devices to meet strict quality and safety standards within the healthcare industry while enhancing the lifespan of the equipment. Solenoid valves also play a part in anesthesia and oxygen therapy machinery, helping to automate critical medical processes and minimize the need for manual intervention.

Solenoids in Aerospace

Resulting in mechanical motion, solenoids have significant applications within the aerospace industry. They’re an important part of propulsion, release, and landing gear mechanisms as well as air- and spacecraft systems for flight control, power distribution, life support, fuel management, payload deployment, and optimal maneuverability. In satellites, solenoids are advantageous for attitude control systems, ensuring stability and precise orientation adjustment, and thermal management systems, facilitating temperature regulation and heat dissipation.

Custom Coils, Inc. Is Your Expert Partner for Solenoid Design & Manufacturing

Solenoids are important devices in much of the technology we use daily. These devices are effective, versatile, and easy to implement in your systems. From conception to production, the experts at Custom Coils will partner with you to determine your specific needs and customize the right solenoid device for your application. Contact us to learn more about our services, or request a quote today.